Carbon nanotubes (CNTs) have captivated the scientific community since their discovery in 1991 by Sumio Iijima. These cylindrical carbon molecules possess exceptional properties, such as high strength, high electrical and thermal conductivity, and large aspect ratios, making them promising candidates for a wide range of applications in electronics, energy storage, and biomedicine. In this blog post, we will delve into the history of CNT research and examine the essential equipment used in modern CNT growth processes, focusing on the chemical vapor deposition (CVD) method.

The Early Days of Carbon Nanotube Research:

The story of carbon nanotubes began long before their official discovery in 1991. In 1952, L.V. Radushkevich and V.M. Lukyanovich published images of hollow graphitic carbon fibers with diameters as small as 50 nanometers. However, due to the limitations of characterization techniques at the time, these findings did not gain significant attention. It wasn't until Iijima's groundbreaking work in 1991 that the scientific community truly recognized the importance of CNTs.

Following Iijima's discovery, researchers worldwide began exploring various methods to synthesize CNTs, including arc discharge, laser ablation, and chemical vapor deposition (CVD). Initially, arc discharge and laser ablation were the primary techniques used to produce CNTs. However, these methods had limitations in terms of scalability and control over CNT structure and properties.

The Rise of Chemical Vapor Deposition:

Chemical vapor deposition (CVD) emerged as a promising technique for the controlled growth of CNTs in the late 1990s. CVD offered several advantages over arc discharge and laser ablation, including the ability to produce aligned CNT arrays, control over CNT diameter and length, and the potential for large-scale production.

In the CVD process, a carbon source gas (e.g., methane, ethylene, or acetylene) is introduced into a reactor chamber along with a catalyst (e.g., iron, cobalt, or nickel) at elevated temperatures (typically 600-1100°C). The catalyst nanoparticles act as nucleation sites for the growth of CNTs, and the carbon source gas decomposes on the catalyst surface, leading to the formation of CNTs.

Essential Equipment for CVD Growth of CNTs:

As CVD became the predominant method for CNT synthesis, the development of advanced equipment played a crucial role in enabling the growth of high-quality CNTs. The following pieces of equipment are essential for the CVD growth process:

- CVD Reactor: The CVD reactor is the heart of the CNT growth system. It consists of a quartz or ceramic tube placed inside a furnace, where the carbon source gas and catalyst are introduced. The reactor's design, including its dimensions, material, and temperature distribution, significantly influences the quality and uniformity of the grown CNTs.

- Catalyst Delivery System: The catalyst nanoparticles are typically delivered into the reactor using either a liquid injection or a solid substrate method. In the liquid injection method, the catalyst precursor is dissolved in a solvent and then injected into the reactor using a syringe pump or an atomizer. The solid substrate method involves depositing the catalyst nanoparticles onto a substrate (e.g., silicon, quartz, or alumina) before placing it inside the reactor.

- Gas Delivery System: Precise control over the flow rates and composition of the carbon source gas and other gases (e.g., hydrogen, argon, or helium) is crucial for optimizing the CNT growth process. Mass flow controllers (MFCs) are used to regulate the gas flow rates, while gas mixing systems ensure uniform distribution of the gases within the reactor.

- Temperature Control System: The growth temperature is a critical parameter in the CVD process, as it influences the catalyst activity, carbon source decomposition, and CNT growth rate. High-precision temperature controllers and thermocouples are used to maintain stable and uniform temperatures throughout the reactor.

- Vacuum System: Many CVD processes are carried out at reduced pressures to enhance the diffusion of the carbon source gas and improve the quality of the grown CNTs. A vacuum system, consisting of a vacuum pump and pressure gauges, is used to control and monitor the reactor pressure.

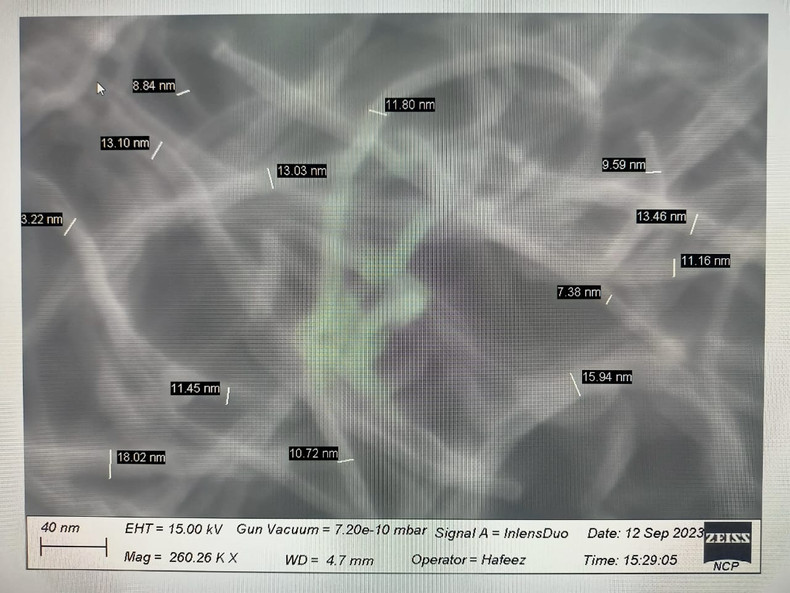

- Characterization Tools: In-situ and ex-situ characterization techniques are essential for understanding the growth mechanism, optimizing the process parameters, and evaluating the quality of the grown CNTs. In-situ techniques, such as Raman spectroscopy and laser-induced incandescence, provide real-time information about the CNT growth process. Ex-situ techniques, including electron microscopy (SEM and TEM), atomic force microscopy (AFM), and X-ray diffraction (XRD), are used to analyze the morphology, structure, and properties of the grown CNTs.

The Importance of Process Optimization:

While advanced equipment is crucial for the growth of high-quality CNTs, process optimization is equally important. Researchers must carefully tune the various parameters, such as temperature, pressure, gas flow rates, and catalyst composition, to achieve the desired CNT properties and yield. This optimization process often involves a combination of experimental studies and computational modeling to understand the complex interplay between the different parameters and their impact on CNT growth.

Recent Advancements and Future Prospects:

In recent years, significant progress has been made in the development of advanced CVD techniques for CNT growth. Some notable advancements include:

- Plasma-Enhanced CVD (PECVD): PECVD utilizes a plasma to enhance the decomposition of the carbon source gas and lower the growth temperature, enabling the synthesis of vertically aligned CNTs at temperatures as low as 400°C.

- Fluidized Bed CVD: This technique involves the use of a fluidized bed reactor, where the catalyst particles are suspended in a flowing gas stream. Fluidized bed CVD allows for continuous production of CNTs and better control over the CNT morphology and properties.

- Floating Catalyst CVD: In this method, the catalyst precursor is introduced into the reactor in the gas phase, along with the carbon source gas. Floating catalyst CVD enables the continuous production of CNTs without the need for a solid substrate.

As CNT research continues to advance, the development of novel equipment and growth techniques will play a crucial role in unlocking the full potential of these remarkable nanomaterials. From high-performance electronics and energy storage devices to biomedical applications and space exploration, the future of CNTs is bright, and the evolution of CNT growth equipment will be at the forefront of this exciting journey.