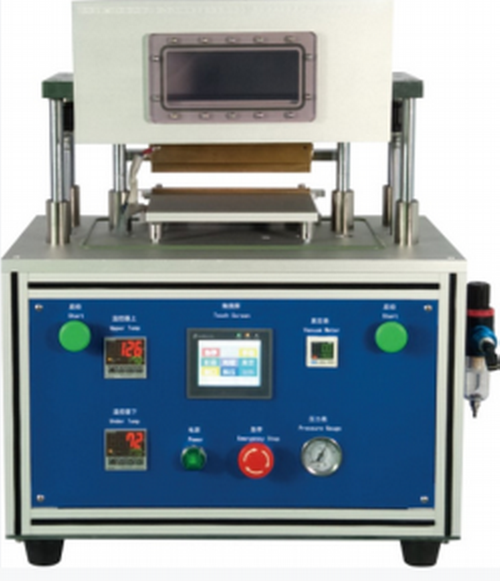

Product Overview

Introducing the revolutionary Omni R&D Low Vacuum Pump System, a state-of-the-art solution designed to deliver unparalleled performance and reliability in applications requiring a high vacuum degree under dry working conditions. This cutting-edge system combines precision engineering, advanced features, and user-friendly operation, making it the perfect choice for industries such as semiconductor manufacturing, coating processes, and research laboratories.

Our Low Vacuum Pump System is a testament to our commitment to innovation and excellence in vacuum technology. Engineered to operate seamlessly in dry environments, this system eliminates the need for additional lubrication or maintenance, ensuring optimal performance and reduced downtime. With its powerful main suction pump function, the Low Vacuum Pump System efficiently handles large volumes of gas, achieving quick evacuation times and maintaining a high vacuum degree. The entrapment vacuum pump exhaust method effectively traps and compresses the evacuated gas, resulting in a clean and environmentally friendly exhaust process. The system's rotary vacuum pump structure offers high pumping speeds, excellent durability, and low noise levels, guaranteeing a smooth and efficient operation.

Features:

- Dry working conditions for optimal performance without additional lubrication or maintenance

- Main suction pump function for handling large gas volumes and achieving quick evacuation times

- High vacuum degree capability for efficient gas removal in various applications

- Entrapment vacuum pump exhaust method for clean and environmentally friendly exhaust processing

- Rotary vacuum pump structure offering high pumping speeds, durability, and low noise levels

- Advanced resistance vacuum gauge with a wide measurement range and fast response time

- Powerful relay contact control, serial communication, and vacuum analog extended functions

- User-friendly operation and easy integration into existing vacuum systems

Specifications:

- Relative air humidity: ≤85%

- Working voltage: 220V±10% 50~60HZ

- Air bleed rate: 8m³/h

- Experiment vacuum: 1.0X10-1Pa

- Oil capacity: 1.1L

- Inlet/Outlet caliber: KF25

- Rotation rate: 1450 rpm

- Noise: 50dB

- Dimensions: 24"x24"x24"

- Resistance vacuum gauge measurement range: 1×10^5 ~ 1×10^-1 Pa

- Resistance vacuum gauge control range: 5×10^3 ~ 5×10^-1 Pa

- Resistance vacuum gauge filament material: Tungsten wire (platinum or nickel chromium optional)

- Resistance vacuum gauge filament temperature: 40~300°C

Equipped with:

- Advanced resistance vacuum gauge (ZJ-52T Pirani gauge) with KF16 quick-release flange

- High-quality rotary vane vacuum pump with KF25 inlet and outlet calibers

- Manual throttle valve for precise vacuum control

- Bellows for flexible and secure connections

- Comprehensive user manual and dedicated technical support