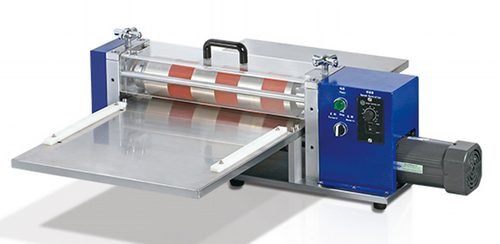

Product Overview

Omni R&D's Hydraulic Balance Electric Roller Machine is a state-of-the-art solution for high-precision rolling of positive and negative electrodes in the battery industry. This innovative equipment ensures exceptional horizontal and vertical uniformity in rolling, consistently delivering high-quality rolled products. Powered by a hydraulic system for roll rolling, this machine is ideal for applications that demand high rolling force and precise rolling gap consistency.

The Hydraulic Balance Electric Roller Machine by Omni R&D is a cutting-edge equipment designed to meet the stringent requirements of the battery industry. With its integral gantry frame and CNC precision machining, this machine guarantees unparalleled precision and stability. The rolls, constructed from imported cold-rolled chrome-molybdenum material, undergo heat treatment, chrome plating, and cryogenic treatment, resulting in high internal and external hardness and excellent wear resistance. The imported hydraulic system automatically controls the rolling pressure, while the patented hydraulic balance rolling mechanism ensures stable pressure holding and outstanding horizontal and longitudinal rolling uniformity. The inclined block type roll gap adjustment device with display adjustment further enhances the machine's precision and user-friendliness.

Features:

- Integral gantry frame and CNC precision machining for high precision and stability

- Imported cold-rolled chrome-molybdenum rolls with heat treatment, chrome plating, and cryogenic treatment for high hardness and wear resistance

- Automatic rolling pressure control via imported hydraulic system

- Patented hydraulic balance rolling mechanism for stable pressure holding and excellent rolling uniformity

- Inclined block type roll gap adjustment device with display adjustment for precision and user-friendliness

Specifications:

- Rolling Force: Max. 25 tons

- Mechanical Speed: Max. 6m/min

- Work Roller Diameter: Φ200mm

- Work Roller Material: 9Cr3Mo

- Surface Hardness: HRC65-70

- Internal Hardness: HRC60-62

- Surface Roughness: Ra≤0.4

- Round Runout: Better than ±2μm

- Roll Width: 330mm (13")

- Depression Type: Hydraulic

- Rolling Precision: ±1.5μm

- Maximum Opening of Rolling Mill: 2mm

- Reducer and Sub-gearbox: Combined type

- Rolling Mill Motor: AC frequency conversion motor

- Single Reduction of Lithium Electrode Sheet: 20-30% (thinner sheets require multiple rolls at 5μm/time)

- Operating Environment: Recommended ambient temperature 25±3°C, humidity 30-90RH, no vibration or electromagnetic interference

- Equipment Dimensions (L×W×H): 1300mm × 500mm × 950mm (51.2" × 19.7" × 37.4")

- Voltage: 220V, 2KW

- Compressed Air: 0.5-0.8MPa

- Weight: Approximately 600kg (1,323 lbs)

Equipped With:

- Hydraulic system

- AC frequency conversion motor

- Reducer and gearbox

- Precision coupling

- Pressing device

- Roll system

- Rolling mill body

- Protective plate

- PLC touch screen

- Electrical control