Product Overview

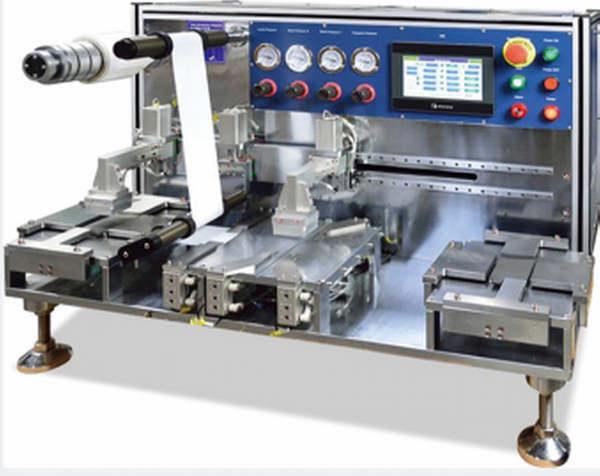

Omni R&D's Semi-Automatic Lamination Stacking Machine is a cutting-edge solution for the Z-shaped lamination assembly of positive and negative electrodes and separators in lithium batteries. This innovative equipment seamlessly integrates manual loading with fully automatic pole piece position correction and lamination processes, ensuring high lamination efficiency and precision. Designed to stack batteries up to 200mm × 200mm (7.8" × 7.8"), the machine's adjustable fixtures accommodate different sizes, making it ideal for research and development and sample production of laminated lithium-ion batteries. With its single cantilever structure design, automatic constant tension control for coil material isolation film, and automatic correction control, this machine is a game-changer in the battery manufacturing industry.

The Semi-Automatic Lamination Stacking Machine by Omni R&D is a versatile and user-friendly equipment that streamlines the Z-shaped lamination assembly process for lithium battery electrodes and separators. The machine's compatibility design allows for easy adjustment of the positioning fixture to accommodate various battery sizes, offering a wide range of flexibility. With PLC control and HMI operation, the machine is intuitive to use and maintain. The operator manually loads the pole piece, while the machine automatically positions, picks up the laminations using a manipulator, and performs automatic stacking. The coil diaphragm is controlled by an automatic servo constant tension system, and the diaphragm itself is managed by an automatic photoelectric correction control. This combination of features ensures consistent, high-quality lamination results with minimal manual intervention.

Features:

- Automatic control of the number of laminations based on preset values

- Compatibility design for easy adjustment to accommodate various battery sizes

- PLC control and HMI operation for user-friendly interface and maintenance

- Manual pole piece loading with automatic positioning, lamination pickup, and stacking

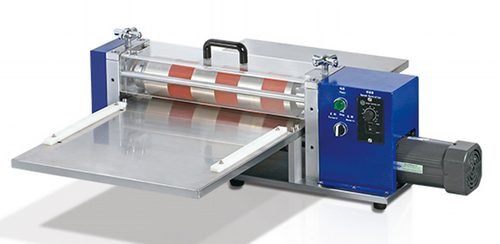

- Automatic servo constant tension control for coil diaphragm

- Automatic photoelectric correction control for diaphragm

- Z-shaped lamination method for efficient assembly

- Manual loading with automatic manipulator lamination and diaphragm pulling

Specifications:

- Lamination Accuracy Uniformity: ≤±0.3mm

- Lamination Range (Battery Size): Min. 80mm × 80mm (3.1" × 3.1"), Max. 80mm × 160mm (3.1" × 6.2"), without pole lug

- Maximum Lamination Thickness: 30mm (1.18")

- Maximum Number of Laminated Layers: 500 (adjustable)

- Maximum Diaphragm Diameter: 250mm (9.8")

- Diaphragm Core: 3-inch core, clamped by air shaft

- Coil Diaphragm Control: Automatic servo constant tension

- Diaphragm Control: Automatic photoelectric correction

- Equipment Dimensions (L×W×H): 1000mm × 780mm × 750mm (39.3" × 30.7" × 29.5")

- Equipment Weight: Approximately 400kg (882 lbs)

- Power Supply: Single-phase AC 220V±10% (customizable to 110VAC), 50Hz/60Hz, 0.6KW

- Air Source: 0.5~0.8MPa compressed air

- Operating Environment: Recommended ambient temperature 25±3°C, humidity 30~90% RH, no vibration or electromagnetic interference