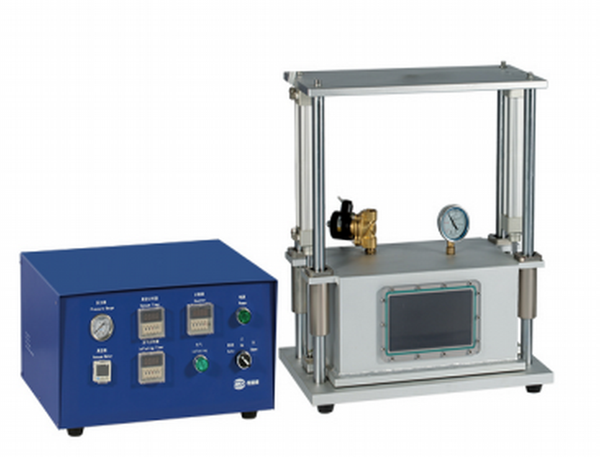

Product Overview

Omni R&D's Vacuum Liquid Injection and Standing Machine is a state-of-the-art solution for the liquid injection and static process of battery capacitors. This innovative machine employs a vacuum-first approach, followed by liquid injection and static processing, ensuring high precision, consistent absorption, and unparalleled reliability in electrolyte handling.

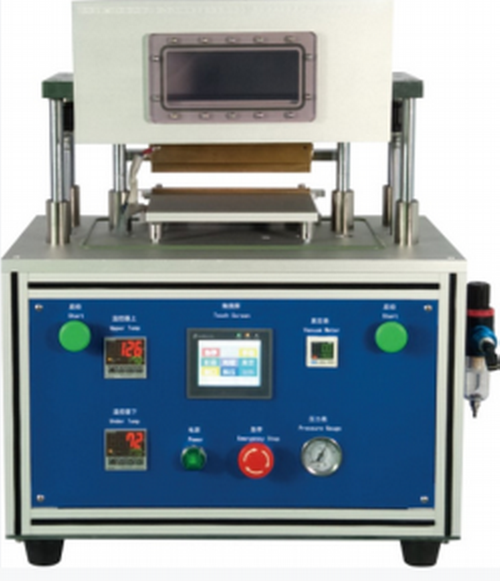

The Vacuum Liquid Injection and Standing Machine by Omni R&D is a versatile and efficient equipment that combines liquid injection and static functions in a single unit. With its high metering accuracy and repeatability, this machine guarantees precise and consistent results. The vacuum-first, then liquid injection process, coupled with a multi-station design, enables high-efficiency operation, accurate precision, and convenient, reliable performance. The machine's high injection precision and chemically resistant hoses connecting the inlets and outlets make it suitable for use in glove boxes or dry rooms. The exquisite and attractive appearance, combined with stable performance, makes this machine a valuable addition to any battery manufacturing facility. The user-friendly PLC and touch screen interface allow for flexible parameter settings and a highly automated program, streamlining the entire process.

Features:

- Combines liquid injection and static functions in a single machine

- Exceptional metering accuracy and repeatability for precise results

- Vacuum-first, then liquid injection process for consistent absorption

- Multi-station design enables high-efficiency operation

- High injection precision ensures accurate electrolyte dosing

- Chemically resistant hoses for inlet and outlet connections

- Suitable for use in glove boxes or dry rooms

- Attractive appearance and stable performance

- PLC and touch screen interface for flexible parameter settings and automation

Specifications:

- Compatible with lithium battery products (cylindrical or pouch)

- Adjustable static low and high vacuum and time (up to 9,999 min)

- Battery Application Range: Length 20-240mm (0.79-9.45"), Width 20-200mm (0.79-7.87"), Thickness 0-15mm (0-0.59")

- Standard 7 stations, allowing completion of 7 products in one operation

- Capacity Range: 0.2ml to infinity (adjustable based on injection pump)

- Cell Injection Volume: 0.2g to infinity (adjustable based on injection pump)

- Injection Accuracy: ±1%

- Spit Speed: 6ml/s (adjustable)

- Inlet and Outlet Pipe: Φ6 pipe

- Adjustable Stroke: X-axis maximum stroke 0-90mm (0-3.54") for centering

- Key parts made of stainless steel 304 and 316 corrosion-resistant materials

- Vacuum chamber welded with aluminum for a stable, corrosion-resistant structure

- Dimensions (L×W×H): 510mm × 400mm × 650mm (20.08" × 15.75" × 25.59")

- Power Requirements: AC 220V/50Hz/0.5KW

- Weight: 90kg (198.4 lbs)

Equipped With:

- Cylinders and solenoid valves

- Vacuum components

- PLC control system

- Touch screen interface

- Analog vacuum gauge

- Motor