Product Overview

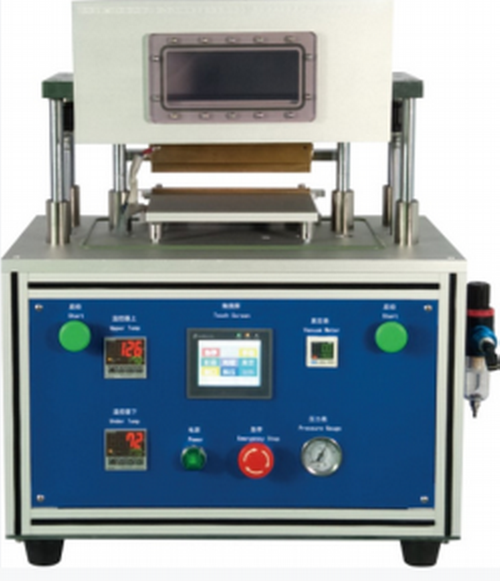

Omni R&D's Vacuum Pre-Sealing Machine is a state-of-the-art solution for vacuumizing and hot-pressing pre-packaging of pouch lithium cells following liquid injection and standing processes. This innovative machine automates the vacuum heat-sealing of battery aluminum-plastic shells through precise control of the main vacuum pumping box and pneumatic heat-sealing components, ensuring consistent and reliable results.

The Vacuum Pre-Sealing Machine by Omni R&D is a highly efficient and energy-saving equipment designed to streamline the pre-packaging process of pouch lithium cells. The machine's head, constructed from copper material, offers superior heat transfer capabilities, reducing power consumption and improving work efficiency compared to similar products. The pressure of the upper and lower heads can be easily adjusted using a pressure regulating valve, accommodating various process parameter requirements. The heads are driven by cylinders and guided by two linear guide sleeves, ensuring flexible and accurate up and down movement while maintaining parallelism after edge banding. A see-through window allows operators to monitor changes in the cavity during operation, while the cover cavity, driven by a cylinder and guided by a rotating guide sleeve, guarantees product sealing requirements. The machine's versatility enables it to be applied to batteries of different specifications, with simple and convenient adjustments. The split design of the host and control box allows the machine to be integrated into glove boxes or assembly lines. Despite its advanced features, the Vacuum Pre-Sealing Machine is user-friendly, compact, lightweight, and visually appealing.

Features:

- Copper head construction for excellent heat transfer, energy efficiency, and improved work efficiency

- Adjustable upper and lower head pressure to meet diverse process parameter requirements

- Cylinder-driven and linear guide sleeve-guided heads for flexible, accurate movement and parallelism

- See-through window for real-time monitoring of cavity changes during operation

- Cylinder-driven and rotating guide sleeve-guided cover cavity for precise product sealing

- Adaptable to various battery specifications with simple and convenient adjustments

- Split design of host and control box for integration into glove boxes or assembly lines

- User-friendly operation, compact size, lightweight construction, and attractive appearance

Specifications:

- Vacuum Range: Up to -95Kpa, adjustable (vacuum pump provided by buyer)

- Head Temperature: Room temperature to 250°C, adjustable

- Temperature Control Accuracy: ±2°C

- Heat Sealing Pressure: 0–7Kg/cm², adjustable

- Heat Sealing Time: 0–99 seconds, adjustable

- Edge Width: 5±0.4mm (customizable)

- Maximum Edge Size: 200mm

- Maximum Battery Range: 200mm (7.8") length, 160mm (6.2") width (including air bag position)

- Seal Thickness Range: 60–300μm

- Sealing Thickness Accuracy: Thickness difference between any two packaging points <15μm

- Gas Consumption: Approximately 0.2L compressed gas per seal

- Air Pressure Working Speed: ≥180 times/h

- Power: 300W heating tube, approximately 0.6KW power consumption when heating

- Power Supply: 220V/50Hz

- Compressed Air Source: 0.5–0.8Mpa (power source must match glove box working gas when used in a glove box)

- Dimensions: Work part: 470mm × 485mm × 435mm (18.5" × 19.1" × 17.1"), Control cabinet: 420mm × 325mm × 225mm (16.5" × 12.8" × 8.9")

- Equipment Weight: Approximately 50Kg (110 lbs)

Equipped With:

- PLC touch screen automation control

- Corrosion-resistant and structurally firm aluminum alloy cavity