Product Overview

Introducing the Advanced High-Precision Floating Fluidized Carbon Nanomaterial Production System from Omni R&D, LLC – a state-of-the-art solution for efficient and controlled production of carbon nanomaterials from natural gas feedstocks. Designed for research and development as well as small-scale manufacturing applications, this versatile system offers unparalleled customization options, enabling the optimization of nanomaterial properties to meet your specific requirements.

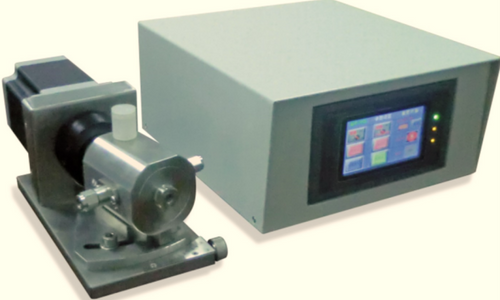

The Advanced High-Precision Floating Fluidized Carbon Nanomaterial Production System is a cutting-edge, lab-scale equipment engineered to facilitate the conversion of natural gas into high-quality carbon nanomaterials. Featuring a modular design, this system comprises several key components, including a gas preheating system, powdered catalyst feeding system, multi-zone heating reactor, and robust product collection system. With advanced temperature control and precise catalyst dosing capabilities, this system ensures optimal process stability and reproducibility.

Key Features:

- Customizable design for tailored carbon nanomaterial production

- Multi-zone heating reactor with advanced temperature control system

- Precise powdered catalyst feeding system for accurate dosing

- Efficient gas preheating system for improved process stability

- User-friendly PLC-based control interface with 15-inch LCD touchscreen

- 30-segment programmable temperature control with PID self-tuning

- Extensive data storage and export capabilities

- Modular construction for simplified maintenance and future upgrades

- Robust product collection system with exhaust and anti-clogging filters

Specifications:

- Reactor Maximum Operating Temperature: 1100°C

- Effective Temperature Zone: 1500mm (3 zones of 500mm each)

- Temperature Control Accuracy: ±5°C

- Adjustable Heating Rate: 1-15°C/min

- Cooling Method: Air and water cooling

- Gas System: 2 channels with high-precision mass flow controllers

- Catalyst Conveying: Screw conveying system for powdered catalysts

- Control System: PLC-based with 15-inch LCD touchscreen interface

- Data Storage: Built-in records, USB export, 60+ days storage

- Capacity: 2kg per batch

Equipped With:

- Gas preheating system with single-zone 440mm heating furnace

- Continuous powdered catalyst feeding system with adjustable motor speed

- 4-way air intake system with customized mass flow meter and filtration units

- Main heating system with customized quartz or stainless steel tube reactor

- Stainless steel product collection system with exhaust and anti-clogging filters

- Advanced PLC-based control system with 30-segment programmable temperature control

- Simplified scaffolding for easy access and maintenance