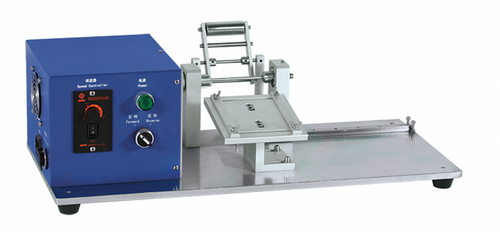

Product Overview

Omni R&D's Plunger Pump Precision Injection System is designed to measure high-end micro liquids such as medicine, electrolyte, acid, solvent, dairy products, glue, reagent and other industries of various liquid media. The high precision electric metering pump uses the connection between the coupling and the stepping motor to drive the reciprocating rotation of the plunger rod in the ceramic cavity, and forms a reciprocating valve switching between the liquid inlet and the liquid outlet, so as to achieve the working purpose of accurately control of the liquid medium in and out. It features:

- Suitable for high-end micro precision liquid medium metering filling, adding, liquid injection, spraying, marking. Valve-free design, the flow is extremely stable, the flow accuracy is within ±3‰

- The pump core material uses special industrial ceramics (zirconia ZrO₂, alumina Al₂O₃), with excellent characteristics of high strength wear resistance, acid and alkali corrosion resistance, high temperature resistance, long service life

- With anti-chemical reaction, contact medium parts are ceramic

- The pump core and pump sleeve are processed by the most advanced nanotechnology and gel injection molding technology, with uniform microstructure and high density. High pairing accuracy, achieve self-sealing, self-moistening of the top ceramic technology, no additional seals and lubricating oil assistance

- The pump sleeve and its components are resistant to acid and alkali etc., and can be used for measuring liquids in various harsh environments

- Positive displacement plunger structure, reciprocating rotation operation, adjust the stroke length/rotation period to change the flow rate size

- No waste, no bubbles, no leakage, no liquid point, no blockage

- The system has powerful functions, multi-capacity and multi-speed selection, which can be converted to reverse transfer liquid

- No dynamic sealing parts and wearing parts, the only moving part plunger rod, easy maintenance

- Adopt imported programmable controller and touch screen man-machine dialogue, convenient parameter setting, stable and reliable performance

- Liquid injection can be measured according to the set parameters, automatically stop the measurement when reaching the specified amount of liquid

- Standard communication interface, can be used independently or easy to communicate with PLC or industrial computer

- Total liquid counting volume =Q stroke amount *N stroke times

- It has the function mode of forward pumping/back pumping/back pumping amount/delay measurement/standby cleaning/capacity counting

- The device is compact and exquisite in appearance, flexible in use, simple in operation, stable in operation, safe and reliable

Technical flow process:

- Power supply and liquid medium preparation → plunger rod rotates to suck liquid into the cavity → plunger rod rotates and through the liquid inlet then close the liquid inlet → plunger rod continues to rotate to drain the liquid out of the cavity → plunger rod rotates and through the liquid outlet then close the liquid outlet.

Specifications:

|

Product type: |

|

|

Pump core material: |

|

|

Pump core performance: |

|

|

Pump core pairing accuracy: |

|

|

Drive mode: |

|

|

Range of speed: |

|

|

Speed control mode: |

|

|

Control display mode: |

|

|

Programming software: |

|

|

Storage performance: |

|

|

Single stroke capacity range: |

|

|

Capacity calculation method: |

|

|

Measuring accuracy: |

|

|

Applicable medium temperature: |

|

|

Drain pipe: |

|

|

Liquid discharging needle: |

|

|

Metering pump size: |

|

|

Controller size: |

|

|

Weight: |

|

|

Applicable power supply: |

|

|

Working environment: |

|

|

Protection class: |

|

|

Security: |

|