Product Overview

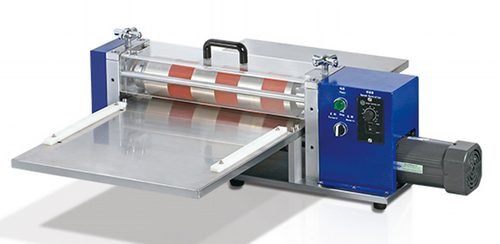

Omni R&D's Semi-Automatic Aluminum Plastic Film Forming Machine is a cutting-edge solution for shell forming of aluminum-plastic film in the production of pouch lithium cells. This innovative machine is designed to deliver high precision, stability, and efficiency, making it an indispensable tool for battery manufacturers seeking to optimize their production processes.

The Semi-Automatic Aluminum Plastic Film Forming Machine by Omni R&D is a state-of-the-art equipment that combines advanced features and user-friendly operation. The machine's four guide pillar structure ensures smooth and precise sliding motions, while the simple and fast mold changing and drawing depth adjustment capabilities minimize downtime. Compared to similar products, this machine enables deeper and more stable stretching of aluminum-plastic film without compromising quality. The precise mold design eliminates common defects such as crow's feet and slumping in the corners and surrounding areas of the formed product. Operator safety is ensured through the use of light curtains and protective covers. The machine is constructed with imported mold materials, high-strength chrome steel, and alloy aluminum, with surfaces treated using environmentally friendly electroplating and baking paint. The sheet metal components feature an exquisite, three-dimensional geometric design that is both simple and visually appealing. Despite its advanced capabilities, the machine is easy to operate, safe, reliable, and compact in size.

Features:

- Four guide pillar structure for smooth and precise sliding motions

- Simple and fast mold changing and drawing depth adjustment

- Deeper and more stable stretching of aluminum-plastic film compared to similar products

- Precise mold design eliminates crow's feet and slumping defects

- Light curtains and protective covers ensure operator safety

- Constructed with imported mold materials, high-strength chrome steel, and alloy aluminum

- Environmentally friendly electroplating and baking paint surface treatment

- Exquisite, three-dimensional geometric design for visual appeal

- Easy to operate, safe, reliable, and compact in size

Specifications:

- Applicable Film Specifications: Length up to 180mm (7"), width up to 150mm (5.9") (customizable)

- Punching Depth: ≤ 6mm (pocket undamaged, PP layer wrinkle-free)

- Equipment Capacity: 200~400 EA/H

- Power Supply: AC 220V/50Hz

- Power Consumption: 100W

- Gas Source: 0.5MPa~0.7MPa

- Equipment Weight: Approximately 150kg (330 lbs)

- Equipment Dimensions (L×W×H): 460mm × 320mm × 925mm (18.1" × 12.6" × 36.4")

Mold Specifications:

- Mold/Core Roughness: 0.4 (mirror reflection)

- Upper and Lower Die Flatness: 0.02mm

- Core Flatness: 0.02mm

- Forming Length Tolerance: ±0.2mm

- Forming Width Tolerance: ±0.2mm

- Molding Thickness Tolerance: ±0.1mm