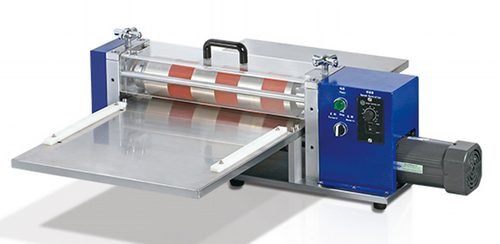

Product Overview

Omni R&D's Pole Die Cutting Machine is suitable for die-cutting of battery positive and negative electrodes. Some of it's main features are:

- Infrared positioning device is used to accurately and conveniently position and die-cut pole pieces;

- It is convenient and fast to replace the knife die;

- The knife mold has a long service life, and the normal use is ≥30,000 times;

- There are no quality defects such as burrs, powder falling, and indentations;

- Between manual and fully automatic, high efficiency 800-2000 pieces/hour;(According to the size of punched pole pieces, 1-8 pieces can be punched each time, and the standard is 2 pieces)

- Adopt four guide pillar structure, slide up and down smoothly and with high precision;

- There is a safety protection light curtain at the material inlet of the equipment, and the operation is very safe;

- Exquisite appearance, sheet metal adopts three-dimensional geometric design, simple and beautiful;

- Easy to operate, safe and reliable, small size;

- Put the pole piece into the die-cutting position, then press the foot valve, the pressurized cylinder drives the die-cutting knife group to go down to automatically cut the pole piece into shape, and the pole piece is taken out to complete.

Specifications:

- Infrared positioning device is used to accurately and conveniently position and die-cut pole pieces

- Vertical burrs≤15μm, horizontal burrs≤20μm;

- The knife mold has a long service life, and the normal use is ≥30,000 times

- Maximum punching size: 11" x 7" (can be customized according to customer requirements)

- Punching accuracy:±0.1 mm

- Booster cylinder:3T

- Die cutting stroke:5.9"

- Pneumatic-hydraulic pressurized cylinder drive, adjustable punching force and punching speed

- Production capacity:800~2000 EA/H(Sheet die-cutting efficiency is slightly lower)

- Power supply:220V/60Hz

- Power:100W

- Compressed air:0.5Mpa~0.8 Mpa

- Dimensions (LxWxH):23" x 18" x 36"

- Weight:400 lbs.

Standard Equipment:

- Mechanical part: feeding guide part, upper mold knife mechanism, lower template mechanism, driving part, guiding part, outer cover frame part, base part, discharging part, etc.

- Electrical control device

- Booster cylinder

- Pneumatic Components

- Bearing moving parts

- Safety light curtain

Maintenance methods and precautions:

- 1. Wipe the die-cutting blades and guide components frequently to keep them clean.

- 2. Lubricate the linear motion parts of the ball guide post and guide bush to keep the movement smooth.

- 3. If it is not used for a long time, wipe the surface of the moving parts of the mechanism clean, and spray the surface with anti-rust oil for protection.

- 4. Regularly check the screws, nuts, pins and other fasteners in each part of the machine to prevent loosening and prevent machine quality accidents and personal accidents.

Warranty Information

One (1) Year Manufacturer's Warranty