Product Overview

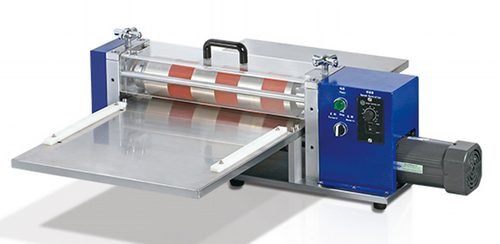

Introducing the Automatic Cross Cutting Machine from Omni R&D, LLC – a versatile and efficient solution for lithium battery positive and negative electrode chip slicing. Designed with advanced automation features and precise cutting capabilities, this machine streamlines the slicing process, allowing for customizable length, quantity, and speed settings to meet your specific requirements.

The Automatic Cross Cutting Machine is an indispensable tool for lithium battery manufacturers, offering seamless integration into electrode slicing workflows. With its automatic unwinding function and tension control system, this machine ensures consistent and reliable material handling, while the adjustable loading speed and air swelling shaft facilitate easy loading and unloading operations.

Key Features:

- Automatic tension adjustment during unwinding for optimal material control

- Continuous cutting with fixed length or cursor tracking options

- Multi-section cutting capability with adjustable pre and post-cut compensation

- Customizable cutting width range from 10mm to 300mm

- Customizable cutting length range from 1mm to 9999mm

- User-friendly PLC human-machine interface for intuitive operation

- Sleek and stylish sheet metal design with three-dimensional geometric elements

- Compact size for space-efficient installation

- Safe and reliable operation with easy-to-use controls

Specifications:

- Unwinding: Fixed gas expansion shaft with automatic tension control for constant tension

- Fixed Length Cutting Speed: 5 - 250mm/s

- Color Chasing Cutting Speed: 5 - 150mm/s

- Maximum Unwinding Diameter: 250mm (9.8")

- Burr Condition: ≤25μm

- Power Supply: 220V/50Hz

- Power Consumption: 1.2KW

- Compressed Air Requirement: 0.5MPa - 0.8MPa

- Applicable Cutting Width: 300mm (11.8")

- Applicable Cutting Length: 1 - 9999mm

- Cutting Accuracy: ±0.3mm (with servo system and color code sensor tracking)

- Overall Dimensions: 700mm x 700mm x 1000mm (27.5" x 27.5" x 39.3") (Guide Plate Length: 800mm, Total Length: 1500mm)

- Weight: Approximately 242kg (535 lbs)

Maintenance and Precautions:

- Frequently clean the cross-cutting blade and guide assembly

- Lubricate the linear moving parts (ball guide columns and guide sleeves) for smooth operation

- Wipe and apply anti-rust oil on mechanism moving parts for long-term storage

- Regularly inspect and tighten screws, nuts, pins, and fasteners to prevent accidents