Product Overview

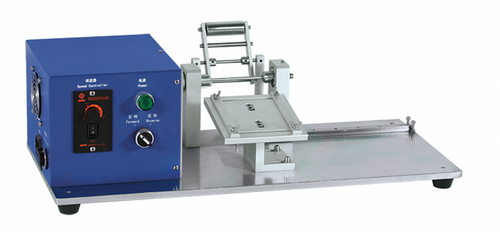

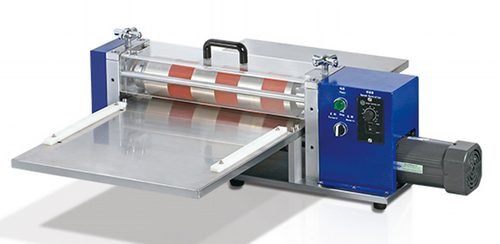

Omni R&D's Intermittent Experimental Coater is a cutting-edge three-roll transfer coating system designed for precision surface coating applications on various substrates, with a special focus on the lithium-ion battery industry. This innovative equipment offers researchers unparalleled convenience and flexibility, enabling both continuous and intermittent coating modes while maintaining the highest standards of coating accuracy and consistency. With its superior drying capabilities, the Intermittent Experimental Coater is the perfect solution for R&D and small-scale testing of lithium-ion batteries, supercapacitors, nickel batteries, and other secondary batteries.

The Intermittent Experimental Coater by Omni R&D is a state-of-the-art coating system that combines versatility, precision, and ease of use. One of its key features is the ability to seamlessly switch between continuous and intermittent coating modes, providing researchers with unmatched flexibility. The system's base material tension control and deviation correction device ensure stable belt running, while the hot air oven with double-sided air blowing delivers exceptional drying results. The three-roll transfer coating mechanism offers a wide coating window, and the comma scraper metering with precision adjustment ensures high coating accuracy. The user-friendly PLC control and touch screen interface make operation convenient and straightforward. An optional solvent recovery treatment unit is available for enhanced efficiency and environmental sustainability.

Features:

- Seamless switching between continuous and intermittent coating modes

- Base material tension control and deviation correction for stable belt running

- Double-sided hot air oven for superior drying performance

- Three-roll transfer coating with a wide coating window

- Comma scraper metering with precision adjustment for high coating accuracy

- User-friendly PLC control and touch screen interface

- Optional solvent recovery treatment unit for enhanced efficiency and sustainability

Specifications:

- Compatible Systems: Ternary, lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, graphite, silicon carbon, and other battery positive and negative plate coating processes

- Coating Method: Continuous coating, intermittent coating, transfer coater

- Oven Sections: 1 section, 1 meter oven

- Coating Speed: 0~0.5 meter/min (depending on drying)

- Substrate Thickness: Aluminum foil (8

30μm), copper foil (830μm) - Roll Surface Design Width: 12.9"

- Guaranteed Coating Width: Within 11"

- Coating Roller, Rubber Roller: Φ4.7"

- Scraping Roller: Φ3.1"

- Coating Accuracy: ±3μm

- Double-sided Coating Film Weight Accuracy: Coating center value ±1.0%

- Slurry Viscosity: 2000~12000 mPas

- Single Side Coating Dry Thickness Range: 20-200μm

- Solvent Properties: Oily solvent NMP (s.g=1.033, b.p=204°C), Aqueous solvent H2O/NMP (s.g=1.000, b.p=100°C)

- Solid Content Range: 20~85%

- Coating Dimensional Accuracy: L≤±1mm, W≤±0.5mm (L: length direction, W: width direction)

- Front and Back Alignment Accuracy: L≤±1mm, W≤±0.5mm (L: length direction, W: width direction)

Equipped With:

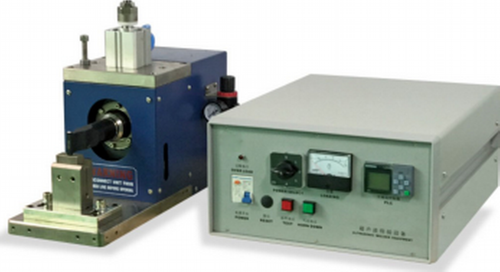

- PLC control system

- Touch screen interface

- Electrical control devices

- Servo motors

- Temperature controllers

- Automatic deviation correction

- Automatic tension control

- Main feeding and receiving material servo motors

- Deep groove ball bearings (machine head)

- Coating rollers

- Back rollers

- Guide rollers

Available Options:

- Solvent recovery treatment unit