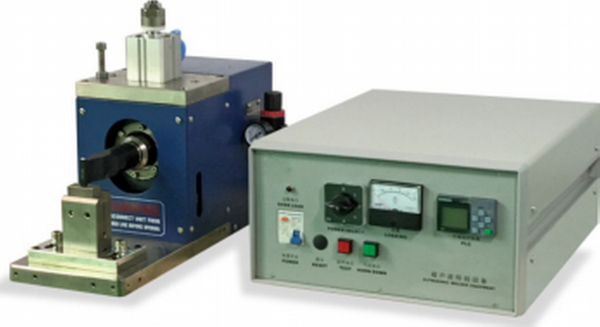

Product Overview

Omni R&D's Ultrasonic metal spot welding machine is generally used for metal welding of winding and lamination processes. It has the characteristics of small size, beautiful appearance, convenient operation, firm structure, stable and safe use. It utilizes the principle of ultrasonic high-frequency vibration friction to convert the energy of ultrasonic vibration into friction energy and transmit it to the metal surface to be welded, a new type of device that activates the molecules of a metal structure sufficiently to form fusion between molecular layers under the condition that pressure is applied while heat is generated by friction.

It features:

- Touch screen interface, intuitive and convenient, automatic frequency tracking.

- No trace of oxidation, ultrasonic cleaning function, metal surface contamination or oxide, no surface treatment, but also perfect welding.

- All workpieces do not need to be pre-treated, and can be welded without solder and solder oil additives, which is economical and convenient.

- The welding head is made of wear-resistant materials for long-lasting durability.

- The internal resistance of the solder joint is small. Good electrical conductivity after welding, its resistivity is extremely low, close to zero.

- The welding time is very short, generally within 0.01-2S seconds, the welding can be completed instantly.

- The solder joint is firm, the working temperature does not exceed its annealing temperature, does not change the metallographic structure of the workpiece, its welding strength is stronger than other methods of welding, and the welding interface is neat and clean.

- Low welding cost, fast speed, easy operation and convenient maintenance.

- No sparks are generated during welding, the operator is safe and at ease, there is no smell of smoke, and it will not cause air pollution.

Specifications:

- Output power:800W (adjustable)

- Welding layer: within 20 layers

- Working temperature:+5°C to +50°C

- Sine Harmonic Parameters:≥97%

- Input power factor:≥80%

- Working frequency:40KHz

- Power supply:AC220V 50Hz

- Mold frequency range:±400HZ(Taking 15KHZ ultrasonic as an example, the mold frequency can be used for automatic frequency tracking at 14.40-15.20KHZ.)

- Automatic frequency tracking accuracy:±5HZ

- Power stability:≤ 5%

- When the remote terminal responds dynamically:≤10ms

- Overcurrent protection current:15A

- Overcurrent protection time:100ms

- Overheat protection temperature:85℃

- Dimension:

- Crate (LxWxH): 17.3" x 7.4" × 11.4"

- Welding Box (LxWxH): 12.9" × 7.4" × 13.3"

- Net weight:80 lbs.

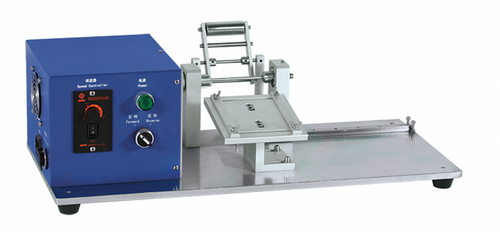

Applicable Welding Range:

- Battery pole pieces: single-point, multi-point, single-layer, multi-layer, square , strip welding and other processes of nickel strip + copper foil, nickel strip + aluminum strip, aluminum strip + aluminum foil, aluminum strip + aluminum cover, aluminum shell + aluminum-nickel composite strip and other materials.

- Welding of automobile terminal blocks, automobile wiring harnesses, motor terminals, relay sheets, electrolysis, capacitor pole sheets, carbon brush sheets, heat sink sheets, copper tubes, copper tubes + aluminum sheets, copper tubes + copper sheets, etc.

Warranty Information

One (1) Year Manufacturer Parts Warranty.