Product Overview

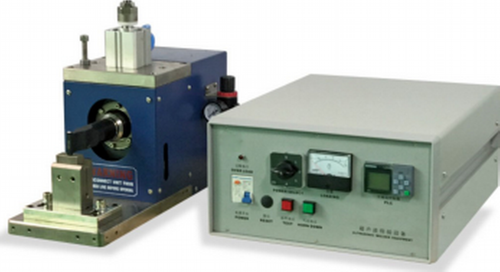

Omni R&D's negative spot welder for cylindrical cell batteries is a widely popular AC pulse spot welder, using microcomputer SCM control, the performance is more stable and reliable, is designed according to the production of high-end nickel-cadmium, nickel-hydrogen, lithium batteries in the world, used for welding cylindrical cell negative case and electrode ear (single needle welding). It features;

- Stable welding current, uniform solder joint size, beautiful solder joint, small spark, no black

- It is an ideal equipment for the production and assembly of lithium batteries to completely overcome the phenomenon of low pressure and water outflow after spot welding of lithium batteries

- Using microcomputer SCM control, can realize single pulse, double pulse and multi pulse welding

- All parameters are set digitally, so the parameter adjustment is intuitive and accurate

- The pressure of the welding needle is adjusted independently and conveniently to ensure the stability and reliability of the welding pressure

- Spot welding is accurate, suitable for small cap cell welding, high yield

- The device is small in size, exquisite in appearance

Usage Example:

- Connect the air source and power supply, and close the switch

- Press the "Up key" to enter the normal working state as shown in the figure

- Parameters setting (have been set in the factory and generally do not need to be set): press the "Mode key" for about 3 seconds, the upper pulse flashes, press the "Up key", "Down key" can set the value, press the "Mode key" to switch the parameter settings, and then long press the "Mode key" for about 3 seconds, the parameters can be saved automatically.

- Adjustment of welding pressure (has been set in the factory and generally do not need to be set): turn the welding pressure adjustment stud, clockwise rotation will increase the pressure, otherwise decrease, adjust the appropriate pressure according to the welding demand.

- Bend the cell current collector in the center of the coil hole, put it into the shell, insert the welding needle directly into the bottom of the shell from the coil hole, and then put the shell on the lower welding plate, press the foot valve, then the upper needle moves down and contacts with the welding needle for welding. (Check whether there is carbon deposit in the welding needle, if there is, remove it with a file or sandpaper, in order to ensure good welding quality, it is necessary to trim the welding needle, and file the tip of the welding needle smoothly with a small file)

Specifications:

- Maximum output power: 10KW

- Welding current: 00 ~ 99

- Power supply: AC220V±10% 50 ~ 60Hz

- Input air pressure: 0.1 ~ 0.7MPa

- Scope of application: suitable for 0.03mm ~ 0.25mm various welding pieces

- Dimension (LxWxH): 16"×23"×16"

- Weight: 110 Lbs.

Warranty Information

One (1) Year Warranty