Product Overview

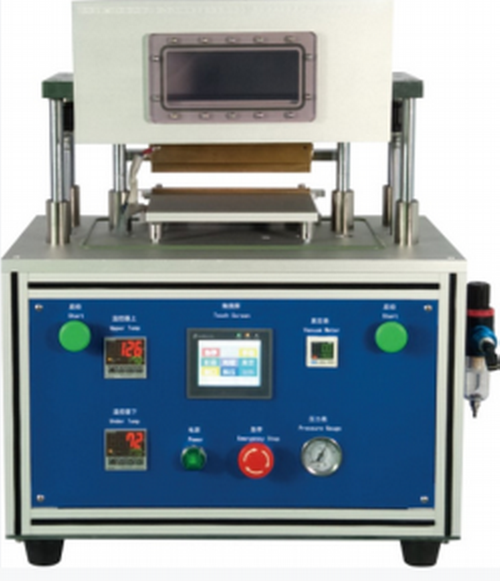

The Omni R&D Multi-Station Containment Glove Box is a cutting-edge solution for demanding research and development applications. This advanced glove box features a spacious dual-station design with single-sided operation, an integrated single-column purification unit, intuitive PLC control, and touch screen operation. Engineered to maintain an ultra-pure environment with water and oxygen content below 1 ppm under standard conditions, this glove box sets a new standard in performance and reliability.

Our Multi-Station Containment Glove Box is a high-performance solution designed to meet the stringent requirements of modern laboratories. Its dual-station design allows for single-sided operation, enabling multiple users to work concurrently without compromising the controlled environment. Constructed from durable, acid-resistant 304 stainless steel, this glove box is built to withstand daily use in demanding settings.

The integrated single-column purification unit efficiently removes contaminants, while the advanced oxygen and water analyzers provide real-time monitoring. The oxygen analyzer (0-1000ppm range) utilizes a long-life, air exposure-tolerant ZrO₂ sensor, and the water analyzer (0-500ppm range) offers easy cleaning and regeneration.

An organic solvent adsorber (136mm dia. x 256mm H) filled with 2kg of activated carbon captures and removes organic solvent vapors. The ergonomic, closed-box design features an inclined operating surface, removable safety glass front window, and LED lighting for optimal comfort and visibility.

The glove box is equipped with a vacuum transition chamber (360mm dia. x 600mm L), a small transition chamber (150mm dia. x 300mm L), and 7 KF40 spare ports for efficient material transfer and integration of additional equipment. Two pairs of chemical-resistant butyl rubber gloves provide a secure and flexible interface for handling materials.

A high-performance circulating fan (90m³/h flow rate) with frequency conversion technology ensures efficient and uniform atmosphere circulation. The RV12 vacuum pump (12m³/h flow rate, ultimate vacuum degree ≤2x10⁻¹pa) can be started manually or via PLC control. A foot switch allows for hands-free operation, while sturdy bracket casters enable easy mobility within the laboratory.

Features:

- Dual-station design with single-sided operation for multiple users

- Integrated single-column purification unit for contaminant removal

- PLC control with touch screen operation for seamless monitoring

- Oxygen analyzer (0-1000ppm) with ZrO₂ sensor and water analyzer (0-500ppm)

- Organic solvent adsorber (136mm dia. x 256mm H) with 2kg activated carbon

- Ergonomic design with inclined surface, safety glass window, and LED lighting

- Vacuum and small transition chambers for efficient material transfer

- High-performance circulating fan (90m³/h) and RV12 vacuum pump (12m³/h)

- Foot switch for hands-free operation and bracket casters for mobility

Specifications:

- Dimensions: 2440mm (L) x 750mm (W) x 900mm (H)

- Material: 304 stainless steel, acid-resistant, 3mm thickness

- Leak rate: ≤0.001 vol%/h

- Oxygen analyzer range: 0-1000ppm; Water analyzer range: 0-500ppm

- Vacuum pump: RV12, 12m³/h flow rate, ultimate vacuum degree ≤2x10⁻¹pa

- Circulating fan: 90m³/h flow rate, frequency conversion technology

- Lighting: LED lights installed above each front window

- Interfaces: 7 KF40 spare ports, 1 power interface (220V)

Equipped With:

- 2 ea. 304 stainless steel cabinets with flanges

- Vacuum transition chamber (360mm dia. x 600mm L) and small transition chamber (150mm dia. x 300mm L)

- 2 front windows with 2 glove ports each, 2 pairs of butyl rubber gloves

- Water analyzer, oxygen analyzer, and organic solvent adsorber

- High-performance circulating fan, RV12 vacuum pump, foot switch, and bracket casters