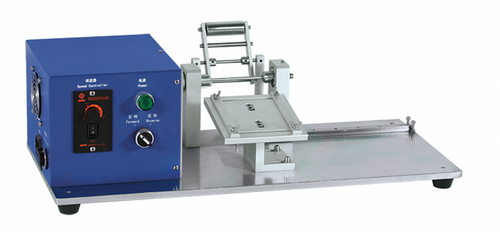

Product Overview

Omni R&D's Plunger Pump Precision Injection System is a state-of-the-art metering solution designed for accurate dispensing of high-end micro liquids in various industries, including medicine, electrolyte, acid, solvent, dairy products, glue, and reagents. This advanced system utilizes a high-precision electric metering pump that leverages the connection between the coupling and the stepping motor to drive the reciprocating rotation of the plunger rod within the ceramic cavity. By forming a reciprocating valve switching between the liquid inlet and outlet, the system precisely controls the flow of liquid medium in and out, ensuring unparalleled accuracy and reliability.

The Plunger Pump Precision Injection System by Omni R&D is a versatile and high-performance metering solution that caters to a wide range of applications, including high-end micro precision liquid medium metering, filling, adding, liquid injection, spraying, and marking. The system's valve-free design ensures extremely stable flow and exceptional flow accuracy within ±3‰. The pump core material, made from special industrial ceramics such as zirconia (ZrO₂) and alumina (Al₂O₃), boasts excellent characteristics, including high strength wear resistance, acid and alkali corrosion resistance, high temperature resistance, and long service life. The system's contact medium parts are ceramic, providing anti-chemical reaction properties. The pump core and pump sleeve are processed using the most advanced nanotechnology and gel injection molding technology, resulting in a uniform microstructure and high density. The high pairing accuracy achieves self-sealing and self-moistening, eliminating the need for additional seals and lubricating oil assistance. The pump sleeve and its components are resistant to acid and alkali, making them suitable for measuring liquids in various harsh environments. The positive displacement plunger structure operates in a reciprocating rotation, allowing users to adjust the stroke length and rotation period to change the flow rate size. The system ensures no waste, no bubbles, no leakage, no liquid point, and no blockage. With no dynamic sealing parts or wearing parts, the only moving part is the plunger rod, making maintenance easy. The imported programmable controller and touch screen man-machine dialogue provide convenient parameter setting and stable, reliable performance. The system can measure liquid injection according to set parameters and automatically stop the measurement when reaching the specified amount of liquid. The standard communication interface allows independent use or easy communication with PLC or industrial computers. The system offers various function modes, including forward pumping, back pumping, back pumping amount, delay measurement, standby cleaning, and capacity counting. The device is compact, exquisite in appearance, flexible in use, simple to operate, stable in operation, and safe and reliable.

Features:

- Valve-free design for extremely stable flow and exceptional flow accuracy within ±3‰

- Special industrial ceramic pump core material with high strength wear resistance, acid and alkali corrosion resistance, high temperature resistance, and long service life

- Anti-chemical reaction properties with ceramic contact medium parts

- Advanced nanotechnology and gel injection molding technology for uniform microstructure and high density

- Self-sealing and self-moistening achieved through high pairing accuracy, eliminating the need for additional seals and lubricating oil assistance

- Acid and alkali-resistant pump sleeve and components for measuring liquids in harsh environments

- Positive displacement plunger structure with reciprocating rotation operation, allowing flow rate adjustment via stroke length and rotation period changes

- No waste, no bubbles, no leakage, no liquid point, and no blockage

- Easy maintenance with no dynamic sealing parts or wearing parts, and only one moving part (plunger rod)

- Imported programmable controller and touch screen man-machine dialogue for convenient parameter setting and stable, reliable performance

- Automatic measurement and stopping based on set parameters and specified liquid amount

- Standard communication interface for independent use or easy communication with PLC or industrial computers

- Various function modes, including forward pumping, back pumping, back pumping amount, delay measurement, standby cleaning, and capacity counting

- Compact, exquisite appearance, flexible use, simple operation, stable operation, and safe and reliable performance

Specifications:

- Product Type: Single head 1 out 1 reciprocating rotary positive displacement industrial ceramic plunger metering pump

- Pump Core Material: ZrO₂, Al₂O₃

- Pump Core Performance: Corrosion resistance, high temperature resistance, wear resistance, high hardness, low friction coefficient, long service life

- Pump Core Pairing Accuracy: 2μm

- Drive Mode: Imported servo motor/stepper motor

- Speed Range: 1-1200rpm reversible forward and reverse

- Speed Control Mode: Pulse

- Control Display Mode: Research and control 4.3 inches touch screen man-machine interface dialogue operation

- Programming Software: Imported programmable controller

- Storage Performance: Permanent memory can store up to 100 formulations of parameters

- Single Stroke Capacity Range: 0μL-10000μL, Max 10000/1 stroke

- Capacity Calculation Method: Total liquid counting volume = Q stroke amount * N stroke times

- Measuring Accuracy: Less than 5‰

- Applicable Medium Temperature: Medium liquid temperature ≤ 250°C (material selection dependent, please indicate when ordering)

- Drain Pipe: PE/Teflon/Liquid inlet inner diameter Φ6, outer diameter Φ8; Liquid outlet inner diameter Φ6, outer diameter Φ8

- Liquid Discharging Needle: Φ2.5/Φ4.0/Φ6.0 (needle and needle length are optional)

- Metering Pump Size: L×W×H 200mm × 130mm × 150mm

- Controller Size: L×W×H 300mm × 230mm × 180mm

- Weight: ≈8kg, including controller and metering pump

- Applicable Power Supply: AC 220V±10%, 50Hz/60Hz (standard); AC 110V±10%, 50Hz/60Hz (optional)

- Working Environment: Temperature 0~40°C, relative humidity < 80%

- Protection Class: IP31

- Security: Password protection and factory recovery function to ensure that the set parameters are not modified at will

Equipped With:

- Plunger Pump Precision Injection System main unit

- Pump core (ZrO₂ or Al₂O₃)

- Drain pipe (PE/Teflon)

- Liquid discharging needle (Φ2.5/Φ4.0/Φ6.0, optional)

- Controller with 4.3-inch touch screen

- Power supply cable

Available Options:

- Pump core material selection (ZrO₂ or Al₂O₃)

- Liquid discharging needle size and length

- Power supply voltage (AC 220V or AC 110V)