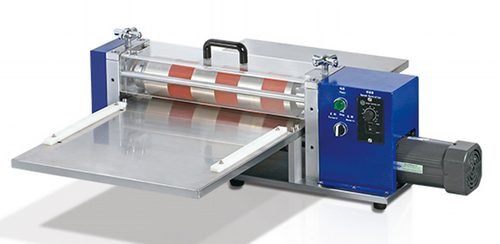

Product Overview

Omni R&D's Semi-Automatic Pole Die Cutting Machine is a revolutionary solution for the precise and efficient die-cutting of battery positive and negative electrodes. This state-of-the-art equipment bridges the gap between manual and fully automatic processes, offering high productivity and consistent quality for your battery manufacturing needs.

The Semi-Automatic Pole Die Cutting Machine by Omni R&D is a game-changer in the world of battery electrode die-cutting. With its advanced infrared positioning device, this machine ensures accurate and convenient positioning and die-cutting of pole pieces. Replacing the knife die is a breeze, and the long-lasting knife mold can withstand ≥30,000 uses under normal conditions. The result is a flawless die-cut product, free from burrs, powder falling, and indentations. Boasting an impressive efficiency of 800-2000 pieces per hour (depending on the size of the punched pole pieces), this machine can punch 1-8 pieces in a single operation, with a standard of 2 pieces. The four guide pillar structure ensures smooth and precise up and down sliding motion, while the safety protection light curtain at the material inlet guarantees operator safety. The machine's exquisite appearance features a three-dimensional geometric design on the sheet metal, creating a simple and beautiful aesthetic. Despite its advanced capabilities, the Semi-Automatic Pole Die Cutting Machine is easy to operate, safe, reliable, and compact in size.

Features:

- Infrared positioning device for accurate and convenient pole piece positioning and die-cutting

- Quick and easy knife die replacement

- Long-lasting knife mold with ≥30,000 uses under normal conditions

- No quality defects such as burrs, powder falling, or indentations

- High efficiency of 800-2000 pieces per hour (1-8 pieces per punch, 2 pieces standard)

- Four guide pillar structure for smooth and precise up and down sliding motion

- Safety protection light curtain at the material inlet for operator safety

- Exquisite appearance with three-dimensional geometric design on sheet metal

- Easy to operate, safe, reliable, and compact in size

Specifications:

- Vertical Burrs: ≤15μm

- Horizontal Burrs: ≤20μm

- Knife Mold Lifespan: ≥30,000 uses under normal conditions

- Maximum Punching Size: 280*180mm (customizable according to customer requirements)

- Punching Accuracy: ±0.1mm

- Booster Cylinder: 3T

- Die Cutting Stroke: 150mm

- Drive: Pneumatic-hydraulic pressurized cylinder with adjustable punching force and speed

- Production Capacity: 800-2000 EA/H (sheet die-cutting efficiency slightly lower)

- Power Supply: 220V/50Hz

- Power Consumption: 100W

- Compressed Air: 0.5Mpa-0.8Mpa

- Dimensions (L×W×H): 580mm × 455mm × 900mm (22.8" × 17.9" × 35.4")

- Equipment Weight: 180kg (397 lbs)

Equipped With:

- Mechanical parts: feeding guide, upper mold knife mechanism, lower template mechanism, driving part, guiding part, outer cover frame, base, discharging part, etc.

- Electrical control device

- Booster cylinder

- Pneumatic components

- Bearing moving parts

- Safety protection light curtain