Product Overview

Omni R&D's Planetary Vacuum Mixer is a revolutionary all-in-one mixing solution that combines the principles of traditional double planetary mixers and high-speed dispersers. This innovative mixer is designed to handle a wide range of materials with low solid content and moderate viscosity, making it an indispensable tool for various industries and applications.

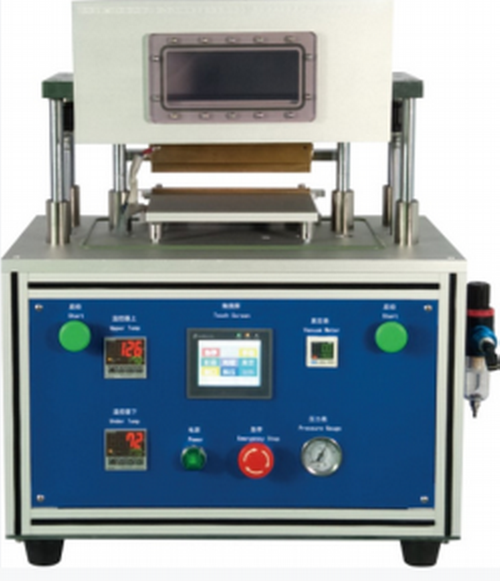

The Planetary Vacuum Mixer by Omni R&D is a powerful and versatile mixing system that offers unparalleled performance and efficiency. Developed with an enhanced power mixer featuring higher speed and greater torque, this mixer ensures optimal mixing results for any medium-viscosity material. The advanced design takes into account critical factors such as agitator rotational speed, stirring power, dispersion linear velocity, suspension level, liquid flow pattern, and turbulence intensity distribution within the barrel. The high-speed dispersion achieves a maximum linear velocity of 23m/s, while the enhanced twist paddle eliminates dead angles and prevents "climbing" phenomena during stirring. The unique combination of mechanical seals and soft, static seals ensures a vacuum environment, enhancing sealing performance by 30%. The Pt100 temperature sensor, in direct contact with the material, provides accurate measurements with a fast response time and an error of only ±0.5°C. The mixer's robust construction includes a base, beam, column, sealing cover, material cylinder, transmission, and electric control system.

Features:

- Combines principles of double planetary mixers and high-speed dispersers

- Enhanced power mixer with higher speed and greater torque

- Maximum linear velocity of 23m/s for high-speed dispersion

- Enhanced twist paddle eliminates dead angles and prevents "climbing"

- Mechanical seals and soft, static seals ensure vacuum and enhance sealing performance by 30%

- Pt100 temperature sensor in direct contact with material for accurate measurements (±0.5°C)

- Robust construction with base, beam, column, sealing cover, material cylinder, transmission, and electric control system

Specifications:

- Vacuum Degree: -0.098MPa, 24h pressure maintaining ≤-80kPa

- Structural Style: Single arm

- Low Speed Shaft: Twist paddle

- Rotating Speed: Revolution: 5

50r/min, Rotation: 5110r/min (Variable frequency speed regulation), High speed: 5~7500r/min (Double high speed) - Linear Guideway: Taiwan HIWIN

- Lifting Method: Linear guide rail material cylinder electric lift (0.37KW reducer)

- Lift Height: 180mm

- Temperature Measurement Method: Barrel wall PT100 sensor in contact with material

- Barrel Positioning: Fixed block of arc-shaped plate for lifting and placing, flange structure on upper barrel for center positioning

- Total Power: 2.5kW

- Power Supply: AC 3*380V, 50Hz

- Dimensions: Length 1100mm, Width 600mm, Height 1300mm

- Weight: Approximately 350kg

Equipped With:

- Cycloidal needle reducer

- Low velocity motor (1.1KW, 1 Set) and high velocity motor (1.5KW, 1 Set)

- Frequency converters (1.1KW, 1 Set and 1.5KW, 1 Set)

- Pt100 temperature sensor

- High-quality bearings, linear guideway, framework oil seal, and valves

- Two sets of mechanical seals

- Precision-ground gears with tooth surface hardening and helical gear drive

- Special high-temperature grease for high-speed bearings

- PLC and touch screen control system