Product Overview

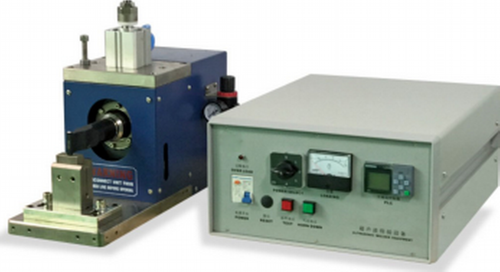

Introducing the Advanced Cylindrical Cell Negative Spot Welder from Omni R&D, LLC – a cutting-edge AC pulse spot welding solution designed for high-end lithium, nickel-cadmium, and nickel-hydrogen battery production. Utilizing microcomputer SCM control, this welder delivers superior performance, stability, and reliability, ensuring precise welding of cylindrical cell negative cases and electrode ears with single-needle operation.

The Advanced Cylindrical Cell Negative Spot Welder is an industry-leading equipment engineered to meet the demanding requirements of modern battery manufacturing. With its advanced microcomputer SCM control system, this welder offers unparalleled versatility, enabling single-pulse, double-pulse, and multi-pulse welding capabilities. All welding parameters are digitally set, allowing for intuitive and accurate adjustments tailored to your specific needs.

Key Features:

- Stable welding current for uniform solder joint size and aesthetically pleasing welds

- Minimized sparking and black mark formation for clean, high-quality welds

- Ideal solution for lithium battery production, preventing low pressure and water outflow issues

- Microcomputer SCM control for single-pulse, double-pulse, and multi-pulse welding

- Digital parameter setting for intuitive and accurate adjustments

- Independent and convenient welding needle pressure adjustment for consistent, reliable welds

- Precise spot welding, suitable for small cap cell welding with high yield

- Compact and sleek design for space-efficient operation

Usage Instructions:

- Connect the air source and power supply, and close the switch.

- Press the "Up" key to enter the normal working state.

- Parameter setting (factory pre-set; adjustment typically unnecessary): Press the "Mode" key for 3 seconds, adjust using "Up" and "Down" keys, switch parameters with "Mode" key, and long-press "Mode" key for 3 seconds to save.

- Welding pressure adjustment (factory pre-set; adjustment typically unnecessary): Turn the welding pressure adjustment stud clockwise to increase pressure, counterclockwise to decrease.

- Bend the cell current collector in the coil hole center, insert into the shell, then insert the welding needle into the shell bottom from the coil hole. Place the shell on the lower welding plate, press the foot valve, and the upper needle will move down for welding contact.

Specifications:

- Maximum Output Power: 10KW

- Welding Current Range: 00 - 99

- Power Supply: AC220V ±10%, 50 - 60Hz

- Input Air Pressure: 0.1 - 0.7MPa

- Suitable for Welding Pieces: 0.03mm - 0.25mm

- Dimensions (L x W x H): 400mm x 560mm x 400mm (15.7" x 22" x 15.7")

- Weight: 45Kg (99 lbs)