Product Overview

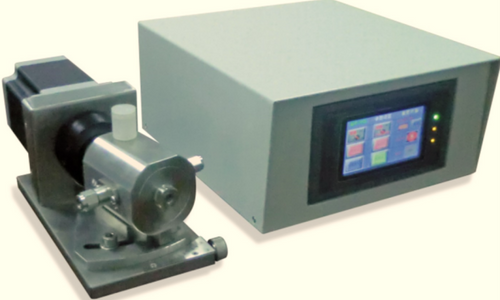

Introducing the ORDSUB-50-5 Sublimator from Omni R&D, LLC, a state-of-the-art equipment designed for efficient and precise sublimation processes. With its advanced temperature control, high-vacuum capabilities, and user-friendly interface, the ORDSUB-50-5 is the ideal choice for researchers and manufacturers requiring reliable and consistent sublimation results.

Our Sublimator is a high-performance equipment that combines advanced temperature control and high-vacuum technology to achieve optimal sublimation results. The system features a compact L-shaped layout, with a length of ≤1550mm, a width of ≤1500mm, and a height of ≤1600mm (excluding tricolor lights). The quartz outer tube, measuring 50mm in diameter, 1200mm in length, and 3mm in thickness, is connected using an embedded groove method with a groove height >5mm and a remote interface with a sliding rail.

The sublimator is equipped with protective devices, including a single-layer metal filter screen for easy cleaning and maintenance, and a vacuum barrier-type cold trap with a 3L capacity, made of stainless steel with both inner and outer bright surfaces. The equipment base is constructed using a "square tube skeleton" with movable wheels and horizontal adjustment feet, and features a glossy stainless steel tabletop (SUS 304).

The thermal field module consists of a cold plate spray-molded furnace shell, with 5 temperature zones above and below and temperature detection at 5 points. The heating program module allows for data output and touch screen temperature setting, with software temperature control protection up to 600°C and hardware support for temperatures >800°C.

Features:

- Advanced temperature control with 5 temperature zones and 5 detection points

- High-vacuum capabilities with a molecular pump (90L/S) and mechanical pump (BSV16)

- User-friendly 10.5-inch touch screen interface for easy control and monitoring

- Protective devices, including a metal filter screen and vacuum barrier-type cold trap

- Compact L-shaped layout for efficient use of space

- Stainless steel construction for durability and easy maintenance

Specifications:

- Overall size: L ≤1550mm, W ≤1500mm, H ≤1600mm (excluding tricolor lights)

- Quartz outer tube: Diameter 50mm, length 1200mm, thickness 3mm

- Temperature zones: 5 sections above and below, temperature detection at 5 points

- Heating program module: Data output, touch screen temperature setting

- Vacuum index: Main chamber <2Pa within 20 minutes (low vacuum), <5x10^-4Pa within 40 minutes (high vacuum)

- Pressure holding test: After reaching maximum vacuum (10^-5Pa), pressure drops below 1Pa after 30 minutes

Equipped With:

- 10.5-inch touch screen control panel

- Molecular pump (90L/S) for high vacuum suction

- Mechanical pump (BSV16) for low vacuum suction

- Vacuum barrier-type cold trap with 3L capacity

- Single-layer metal filter screen for easy maintenance

- High-purity N2 gas for vacuum breaking (0.6Mpa)