Product Overview

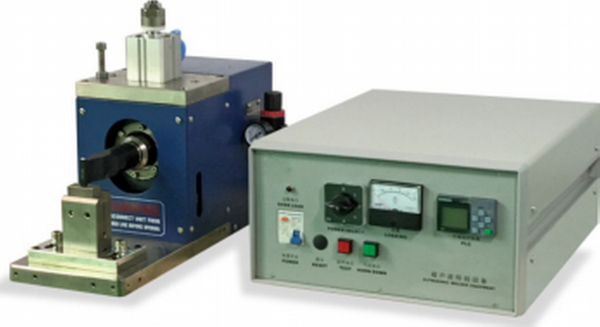

Omni R&D's Ultrasonic Metal Spot Welder is a cutting-edge welding solution designed for metal welding applications in winding and lamination processes. This compact and user-friendly machine boasts a sleek appearance, robust construction, and unparalleled stability, ensuring safe and efficient operation. By harnessing the power of ultrasonic high-frequency vibration friction, the welder converts vibration energy into friction energy, which is then transferred to the metal surface being welded. This innovative device activates metal structure molecules, enabling fusion between molecular layers under the combined influence of pressure and friction-generated heat.

The Ultrasonic Metal Spot Welder by Omni R&D is a game-changer in the world of metal welding. With its intuitive touch screen interface and automatic frequency tracking, this machine offers unmatched convenience and precision. The ultrasonic cleaning function eliminates the need for surface treatment, allowing for flawless welding even on contaminated or oxidized metal surfaces. One of the key advantages of this welder is its ability to weld workpieces without any pre-treatment or the use of solder and solder oil additives, making it an economical and efficient choice. The welding head, constructed from wear-resistant materials, ensures long-lasting durability and consistent performance. The resulting solder joints boast low internal resistance and exceptional electrical conductivity, with resistivity levels close to zero. The welding process is incredibly fast, typically completed within 0.01-2 seconds, enabling instant results. The welder maintains a working temperature below the annealing temperature of the workpiece, preserving its metallographic structure and delivering a welding strength superior to other methods. The welding interface is clean and precise, and the low welding cost, combined with the machine's fast speed, easy operation, and convenient maintenance, make it an attractive option for various applications. Operator safety is paramount, and the Ultrasonic Metal Spot Welder generates no sparks or smoke during the welding process, ensuring a safe and pollution-free working environment.

Features:

- Intuitive touch screen interface with automatic frequency tracking

- Ultrasonic cleaning function for welding on contaminated or oxidized surfaces

- No pre-treatment or solder additives required, ensuring economic efficiency

- Wear-resistant welding head for long-lasting durability

- Low internal resistance and exceptional electrical conductivity in solder joints

- Fast welding times, typically within 0.01-2 seconds

- Firm solder joints with superior welding strength and clean, precise interfaces

- Low welding cost, fast speed, easy operation, and convenient maintenance

- Spark-free and smoke-free welding process for operator safety and pollution prevention

Specifications:

- Output Power: 800W (adjustable)

- Welding Layers: Up to 20 layers

- Working Temperature: +5°C to +50°C

- Sine Harmonic Parameters: ≥97%

- Input Power Factor: ≥80%

- Working Frequency: 40KHz

- Power Supply: AC 220V, 60Hz

- Mold Frequency Range: ±400Hz (e.g., 14.40-15.20KHz for 15KHz ultrasonic)

- Automatic Frequency Tracking Accuracy: ±5Hz

- Power Stability: ≤5%

- Remote Terminal Dynamic Response: ≤10ms

- Overcurrent Protection Current: 15A

- Overcurrent Protection Time: 100ms

- Overheat Protection Temperature: 85°C

- Dimensions: Crate (L×W×H): 440mm × 190mm × 290mm (17.3" × 7.5" × 11.4"), Welding Box (L×W×H): 330mm × 190mm × 340mm (13" × 7.5" × 13.4")

- Net Weight: 35kg (77 lbs)

Applicable Welding Range:

- Battery pole pieces: single-point, multi-point, single-layer, multi-layer, square, strip welding, and other processes involving nickel strip + copper foil, nickel strip + aluminum strip, aluminum strip + aluminum foil, aluminum strip + aluminum cover, aluminum shell + aluminum-nickel composite strip, and other materials

- Welding of automobile terminal blocks, automobile wiring harnesses, motor terminals, relay sheets, electrolysis, capacitor pole sheets, carbon brush sheets, heat sink sheets, copper tubes, copper tubes + aluminum sheets, copper tubes + copper sheets, and more